Yes, you read that right, pervious concrete in SPACE! David Liguori, of BAPC, recently worked with a team from the Microbial Ecology Biogeochemistry Research Laboratory of the NASA Ames Research Center, to design a new form of pervious concrete that is being tested for use in future space flight missions. Space exploration is just one of the areas of research that the laboratory focuses on, their projects can generally be grouped into three main areas: Astrobiology, Space Exploration Technologies, and Green Technologies. Dr. Leslie Bebout and Dr. Tom Murphy were among a team that has been researching the development of oxygen producing machines, that were based off of a synthetic tree concept, called a Self-Adhearing Bioreactors (SABR).

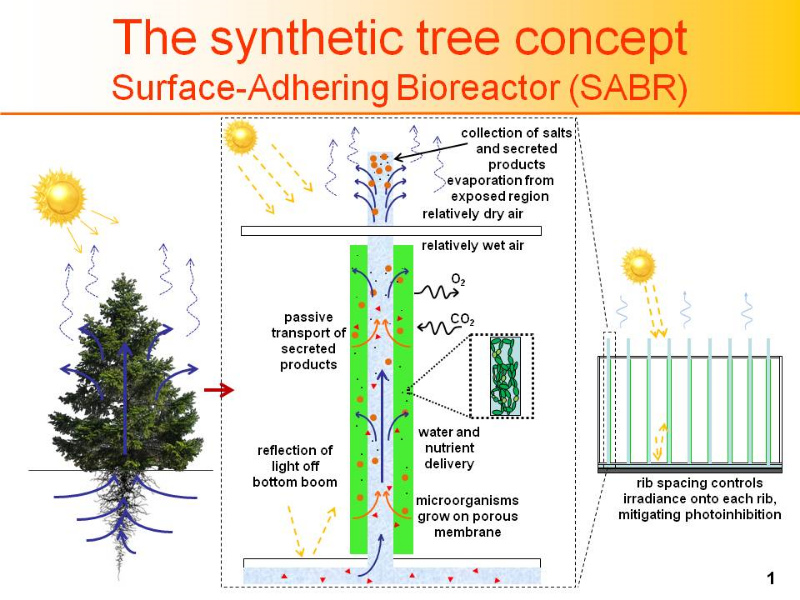

Conceptual schematic of a SABR (NASA)

The SABR uses a simulated transpiration process to deliver water and nutrients to algal biofilms which grow on porous substrates. The biofilm-based cultivation process reduces the water weight by a factor of about 25 compared to conventional algal bioreactors, making SABR an ideal space travel companion. The main goal of SABR project is to deliver lightweight oxygen production for humans in space. If successful, the technology could also be adapted for terrestrial uses, such as algae cultivation for biofuels and food supplements.

Some of the numerous cultivations of algae being studied and grown at the Microbial Ecology / Biogeochemistry Research Laboratory

In order to find the right porous substrate for the SABR's rib panels, the team needed to find a material that allowed the ribs to be absorbent, permeable, lightweight, rigid, durable, and most importantly provide a surface for the algae to thrive on. Originally, they started by using paper-based materials, but the ones they tried fell apart when the algae were scraped off. The team searched for a material that was as strong and durable as rock, and thought of concrete.

Spirulina algae happily growing on the original pervious concrete prototype.

The only issue with using concrete was that conventional concrete would be too heavy, not absorbent, and not porous enough. After researching different concrete products that might solve those two issues Dr. Murphy came across pervious concrete and Bay Area Pervious Concrete. When he contacted us we were all too happy to help the team in their efforts to find a new use for pervious concrete. David, using his advanced knowledge of pervious concrete materials and mix design, created an original prototype to test for the feasibility of algae growth on pervious concrete.

Initial tests showed positive results when the small sample of pervious concrete was placed into similar conditions as they would be in the SABR. In under two weeks the algae showed positive levels of growth on the sample. Pervious concrete appeared to be a feasible solution for the ribs in the SABR. The team requested a full set of concrete ribs to be developed for their SABR prototype.

David continued to experiment with the mix design. The final mix design allowed him to create a permeable concrete rib that was only three millimeters thick, weighting just 108 grams. Thin, lightweight, rigid and durable, just what the team was looking for.

David Liguori and Dr. Thomas Murphy holding BAPC Pervious Concrete SABR ribs in NASA Ames Lab.

The project is currently under the direction of Dr. Leslie Bebout, and full length testing of the SABR prototype, using the BAPC Pervious Concrete rib panels, is now being conducted. If the trials provide positive and replicable results, we could see pervious concrete helping humans to explore beyond this planet.